Features & Benefits

- Inert, toxic, hazardous gases; semi-auto or fully automatic PLC-based control with touchscreen interface

- Single- or double-process panels with optional purge panel

- Supply from cylinder bundles, y-cylinders, tube trailer or tank truck

- Automatic crossover with configurable auto-purge and optional deep pigtail purge

- Life safety relay logic to override PLC for fire, leak, toxic and facility shutdowns with relay feedback

- High-flow and ultra-highflow design

- Optional double isolation for all process valves

- Optional communication protocols

- Modular construction to facilitate service and maintenance

- SEMI-S2 compliant

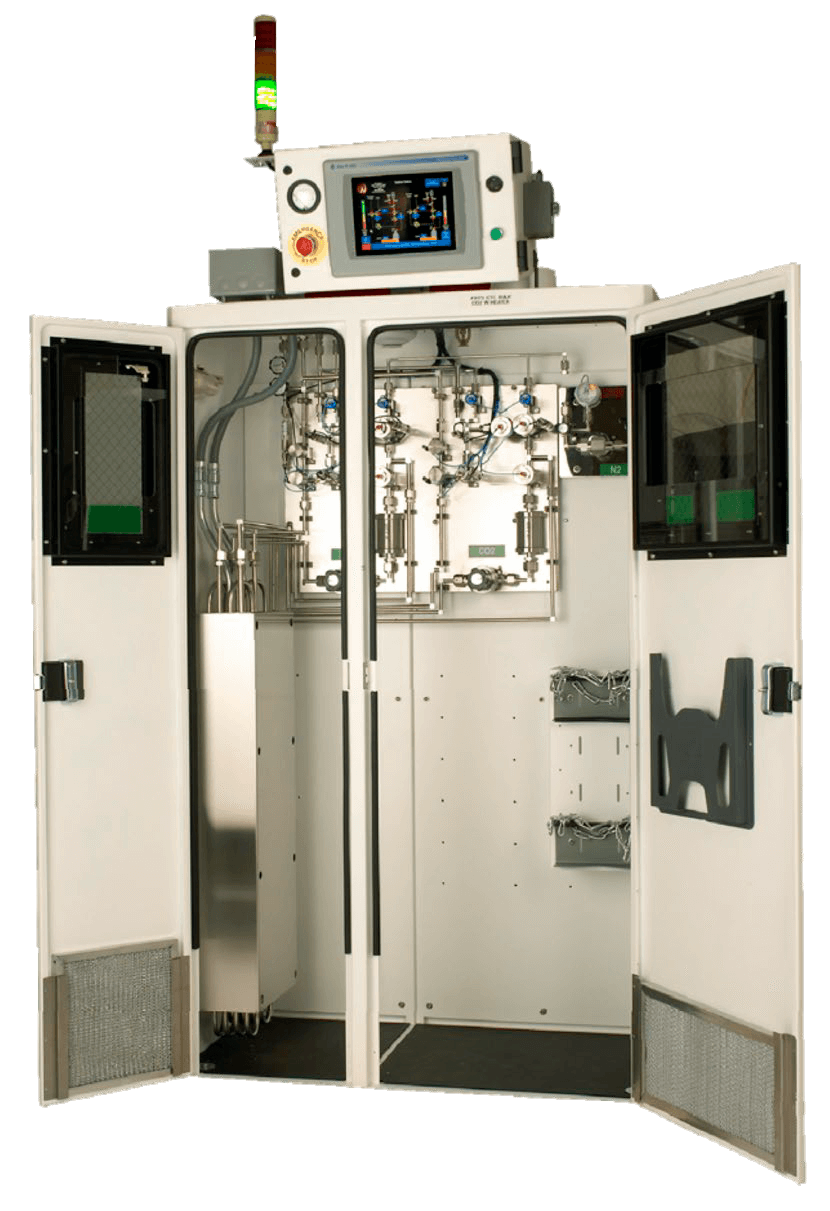

Bulk Specialty Gas System

The Bulk Specialty Gas System (BSGS) is a state-of-the-art distribution system designed for safe, automatic delivery of bulk specialty gases. The PLC-based controller provides the operator with intuitive, easy-to-use touchscreen and on-screen prompts to simplify operator interaction with the machine. The graphical interface allows an operator to quickly determine the status of the tool with a glance at the screen. The panel buttons and on-screen menus offer easy access to any of the controller screens.

The BSGS is designed to distribute gas to a distribution line from one or two bulk supplies, such as various configuration of cylinder bundles, y-size cylinders or tube trailers. The system can be configured for high-flow or ultra-high-flow applications with dualstage pressure regulators, block heaters and source heater controls. CollabraTech designs its systems to ensure the best uptime in the industry with the most stable supply record. The system software is designed to improve efficiency and extend the lifetime of the tool. Contact CollabraTech for more information about a system that matches your needs.

BSGS Enclosure Features

- Superior construction – 11-gauge cold-rolled steel, all-welded construction, polyester powder coating for superior corrosion resistance

- Large windows – Self-closing, self-latching with ¼” safety glass

- Doors – Self-closing, self-latching with enclosure gasket with full-length hinge for years of trouble-free service

- Cabinet louvers – Air intake on door bottom and bottom rear of the enclosure evacuates gases through the rear plenum and eliminates dead areas

- Exhaust sensor – Alarm can initiate chemical shutdown, audible alarm or remote alarm as needed

- Sprinkler head – U.L. approved

- Optional rack or stainless steel cabinet designs

- SEMI-F14 compliant

BSGS Enclosure Specifications

- Three-cylinder enclosure – 42” W x 23” D x 89” H with dual 6” exhaust

- Three-cylinder gas rack – 42” W x 23” D x 89” H Optional VMB Accessories

- Door/window sensors – Provide programmable alarm if door or window is opened

- Toxic monitor – Monitors enclosure continuously for any sign of toxic leak

- Fire sensors – Standard rate of rise or optional UV/IR or dual IR sensors

- Scale platforms for y-cylinders in single- or multiple-cylinder configurations, tube trailer or tank-truck scale system

- Single- or dual-loop heaters to increase component reliability and responsiveness for liquefied compressed gases under high-flow conditions

- Source gas cylinder heating blankets for liquefied compressed gases to stabilize vapor pressure under high-flow conditions

- VMBs for efficient distributions

- Flow meters for total flow and usage tracking

For more information: 602.437.8500 or email info@collabratech.com

Spec Sheets

CASE STUDIES

MORE INFO

- New Liquid Chemical Delivery System for Semi Manufacturing

- Collabratech Announces the Dominus® Gas Delivery System

- Direct Controller Replacement Solution to Extend Life of Legacy Gas Distribution Systems

- CollabraTech Earns ISO 9001 Certification

- CollabraTech ISO 9001 Certificate

- CollabraTech Terms and Conditions of Sale

- Supplier Terms and Conditions

- CollabraTech Brochure